As a veteran electrician with over a decade of experience working with electricity, I’ve observed a widespread yet extremely dangerous phenomenon: many users—even some novice colleagues—have grown accustomed to seeing fittings overheat at transformers, switches, and line joints.

“A little heat is normal”—this is the most fatal misconception. Heating in fittings is absolutely not a “normal phenomenon”; it’s the sharpest warning signal your circuit is sending you. At best, it accelerates insulation aging and wastes energy; at worst, it can cause fuses to blow, fires, or even explosions.

Today, we’ll dissect those installation details that cause fitting overheating yet are most easily overlooked. This isn’t just technical work—it’s a matter of conscience.

Misconception:“Screws? The tighter the better. More force equals more safety.”

Truth: This is the number one cause of overheating. Hardware connections—especially aluminum busbars, copper-aluminum transition clamps, and similar components—have a specified torque rating. This value isn’t arbitrary; it’s determined through precise calculations.

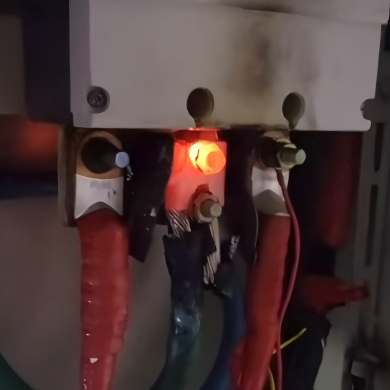

Hazards of Under-Tightening: As shown in Figure 1, contact resistance increases dramatically, generating significant heat when current flows—a basic principle.

1.Metal creep:Both aluminum and copper are relatively soft metals. Excessive pressure causes “creep”—a slow deformation of the metal. While initial contact may seem secure, creep reduces contact pressure over time, paradoxically increasing resistance.

2.Reduced effective contact area: Imagine pressing two flat surfaces too tightly—the edges deform and lift, actually decreasing the area of true, tight contact.

3.Damage to gaskets or components: Directly crushing contact surfaces or sealing rings.

Repeat three times for emphasis. Strictly adhere to the torque values provided by the equipment manufacturer. Employ a diagonal, staged tightening method to ensure uniform pressure distribution. Eliminate the practice of “tightening by feel.”

This chart serves as a general technical reference only and does not replace professional engineering judgment. Electrical work involves risks to personnel and equipment safety. Before performing any tightening operation, always prioritize consulting and adhering to official data in site work procedures, design drawings, and product manuals.

The table below lists recommended torque values for bolts of different specifications. Unit: Newton-meters (N·m)

| Bolt Size (Metric) | Common Strength Grade | Recommended Torque Range (N·m) | Application Notes / Typical Scenarios |

| M6 | 4.8 / 5.8 | 5 – 8 | Small terminals, instrument mounting, control panel faces, lightweight cable ties |

| M8 | 4.8 / 8.8 | 10 – 20 | Small clamps, outdoor terminal boxes, surge arrester lead connections |

| M10 | 8.8 | 25 – 40 | Grounding clamps, low-voltage clamps, small disconnect switch connections |

| M12 | 8.8 | 50 – 70 | Medium clamps, suspension clamp secondary bolts, distribution transformer wiring |

| M16 | 8.8 | 150 – 200 | Tension clamps, connection fittings, main bolts for equipment clamps |

| M20 | 8.8 | 300 – 400 | Large tension clamps, rigid busbar fittings, critical structural connections |

| M24 | 8.8 | 500 – 600 | High-tension fittings, substation heavy equipment connections |

| M30 | 8.8 | 900 – 1100 | Heavy-duty fittings for critical sections like UHV lines and long spans |

Misconception:“New fittings are installed straight out of the box—they look perfectly clean.”

Truth: Any metal exposed to air rapidly forms an oxide layer. Though seemingly insignificant, this layer has extremely high resistivity—tens to hundreds of times that of pure metal.

① Aluminum oxide layer (Al₂O₃): Exceptionally dense and hard, with immense resistance, it is the primary cause of aluminum conductor heating.

② Copper oxide layer (CuO): Similarly significantly increases contact resistance.

Correct Practice:

1.Thorough Cleaning: Before installation, carefully sand the contact surfaces with fine sandpaper or a wire brush to remove all oxidation layers until a metallic sheen is exposed.

2.Immediate Application of Electrical Compound Grease (Conductive Paste): Apply immediately after cleaning. Conductive paste serves three critical functions:

① Isolates the metal from air to prevent re-oxidation.

② Fills microscopic gaps to increase the actual conductive area.

③ Conductive particles like zinc powder further enhance conductivity.

3.Never use non-specialized greases like petroleum jelly or butter. These insulate, attract dust, and counteract the intended effect.

Misconception: “Screws tightened means connection complete.”

Reality: Many fittings endure additional mechanical stress from busbars or cables after installation. Examples include overlong busbars exerting pressure, cables with insufficient bending radius causing rebound force, or equipment vibration during operation.

These persistent forces at connection points may eventually lead to:

① Bolt loosening and reduced contact pressure.

② Micro-cracks forming in the fitting body or contact surfaces.

③ Placing contact points in unstable stress states, accelerating aging.

Correct Practice:

During installation, ensure busbars and cables follow natural, smooth paths without forced pulling or bending. Use flexible connections or appropriate support points to eliminate these extra stresses. After installation, gently shake the assembly to detect any unnatural tension.

Misconception: “Flat washers and spring washers? Just install them—no big deal”

Truth: Washers are critical for ensuring even pressure distribution and preventing loosening.

① Missing or incorrectly installed flat washers (spring washers): Flat washers increase contact area to prevent bolt heads from crushing soft metals (e.g., aluminum). Spring washers prevent vibration-induced loosening. Missing or reversed installation (commonly placing flat washers beneath spring washers) drastically reduces anti-loosening effectiveness.

② Using “open-end spring washers”: In electrical connections, the sharp edges of these washers may damage contact surfaces, making them suboptimal. Disc spring washers are recommended instead, as they provide more consistent and stable clamping force, offering superior resistance to creep and loosening.

Correct Practice:

Strictly follow the assembly sequence: “bolt → flat washer → spring washer → flat washer → nut”(may vary slightly per design). For critical applications involving vibration or thermal cycling, upgrade to disc spring washers.

Misconception: “Copper and aluminum can be screwed together directly without issues.”

Truth: Copper and aluminum are metals far apart in the electrochemical series. When they come into direct contact in moist air (an electrolyte), they form a galvanic cell.

① Aluminum acts as the anode (negative electrode), accelerating corrosion and forming non-conductive aluminum oxide powder.

② Copper acts as the cathode (positive electrode) and remains largely unaffected.

This process rapidly degrades the contact point, causing resistance to skyrocket and temperatures to surge dramatically. It’s a slow yet irreversible “cancer.”

Correct Practice:

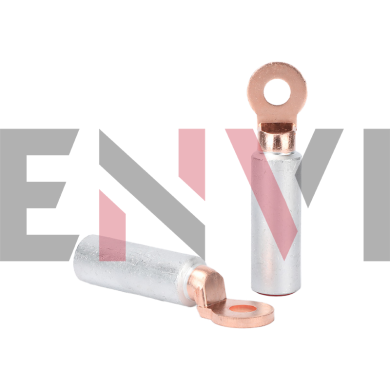

Direct copper-aluminum connections are strictly prohibited! Use copper-aluminum transition plates or transition connectors. These transition components achieve molecular-level bonding through processes like friction welding, fundamentally eliminating electrochemical corrosion.As shown in Figure 2, this is a copper-aluminum transition terminal made by friction welding technology.

Heating in fittings may seem minor, but it reflects systemic installation quality. Remember these five details to avoid 90% of pitfalls:

1.Let mechanics decide:Forget feel—trust torque wrenches.

2.Treat contact surfaces well: Cleaning + conductive paste—neither can be skipped.

3.Eliminate internal stress: Let connection points “relax” without external force.

4.Value the small players:Use washers correctly to ensure sustained pressure.

5.Avoid mismatched pairings: Always use transition fittings for copper-aluminum connections.

Electrical safety is no trivial matter. Every compliant installation is a commitment to equipment and personal safety.