Have you ever noticed that the silver transmission lines crisscrossing cities and wilderness aren’t suspended in empty space? They are firmly connected, supported, and protected by a series of sturdy metal components—the “joints” and “armor” of the power system: electrical hardware.

From inconspicuous screws to complex insulator strings, these fittings may be small, yet they maintain the physical connections and electrical safety of the entire grid. If they operate while “carrying defects,” minor issues can trigger line failures, while major ones may cause tower collapses and broken lines, leading to widespread blackouts. Next, we’ll dive into frontline operations to uncover the top ten common defects in electrical fittings and their on-site troubleshooting methods.

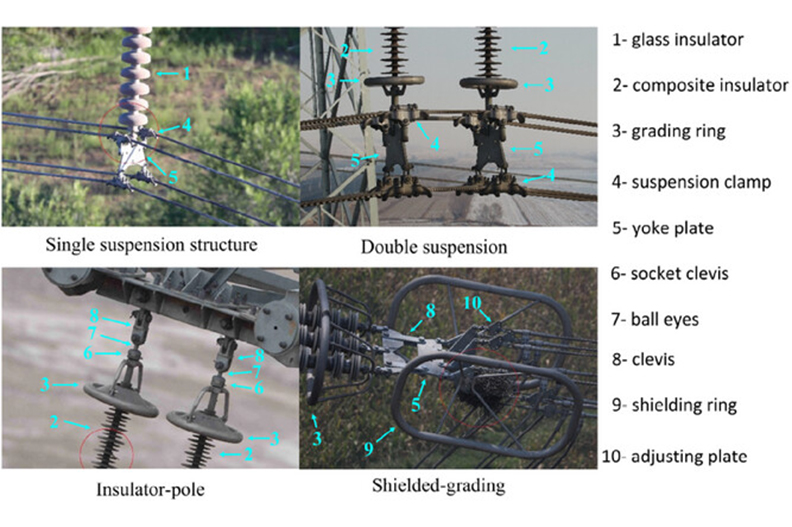

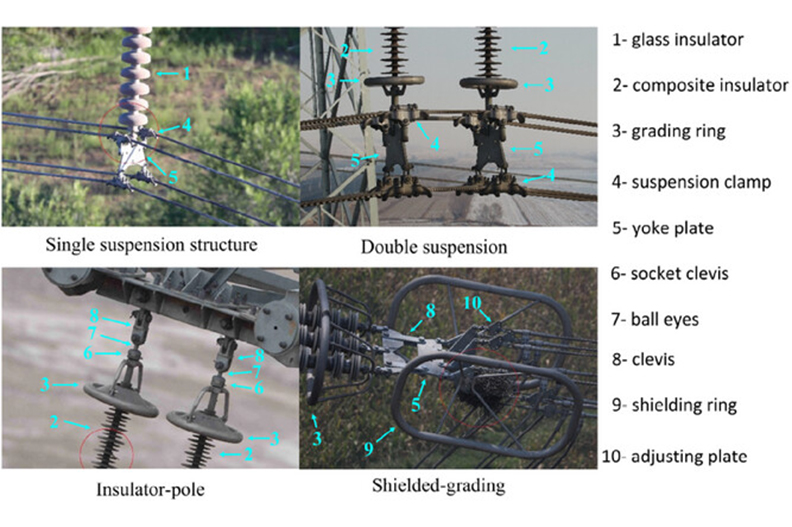

Electrical fittings are primarily categorized by function:

Suspension Fittings: Such as suspension rings and suspension plates, used to suspend conductors from towers.

Suspension Fittings: Such as suspension rings and suspension plates, used to suspend conductors from towers.

Clamping Fittings: Such as various clamps, responsible for gripping conductors or ground wires.

Connecting Fittings: Such as U-clamps and ball-end suspension rings, bearing the responsibility of mechanical connections.

Protective Fittings: Such as vibration dampers and spacers, protecting conductors from vibration and abrasion.

Splicing Fittings: Used to connect broken conductor ends.

These components endure constant exposure to wind, frost, rain, snow, lightning, and electrochemical corrosion, where defects often originate.

Field inspectors serve as the grid’s “doctors,” primarily relying on “observation, instrumentation, and experience” for diagnosis. Below are ten prevalent defects:

Typical Symptoms: Yellowish-brown rust on hardware surfaces, white aluminum oxide powder, or verdigris on copper. Severe cases exhibit structural thinning and brittleness.

Inspection Focus: Focus inspections on tower bases, damp shaded areas, and heavily soiled zones. Gently tap with a rust hammer to detect dull sounds indicating internal corrosion. Use a thickness gauge when necessary.

Typical Symptoms:Fine to visible cracks—or complete fractures—may occur, especially in high-tension areas (e.g., UT clamps, tension clamp steel anchors).

Inspection Focus: Carry high-powered binoculars or use drones for close-range photography. For critical areas, conduct detailed inspections after power disconnection using dye penetrant testing or ultrasonic testing.

Typical Symptoms:Poor conductor-to-clamp contact increases resistance, causing sustained heating. Symptoms include darkening of the clamp surface (bluish or black discoloration), paint blistering, or visible metal fusion marks. Night patrols can clearly identify hotspots using infrared thermometers or thermal imaging cameras.

Inspection Focus: Infrared temperature measurement is the standard method. Generally, a temperature difference exceeding 10°C or an absolute temperature exceeding 90°C constitutes a major defect requiring urgent attention.

Typical Symptoms: Physical wear (e.g., heart-shaped rings grinding conductors) or bending deformation (e.g., straightened suspension rings) due to prolonged vibration, wind sway, or external impacts.

Inspection Focus: Compare fittings against standard shapes. Check for slippage of vibration dampers or loosening of spacer rod clamps, which can cause secondary wear.

Typical Symptoms: Missing or improperly tightened bolts/pins causing connection failure. Common occurrences include fallen vibration dampers and detached spacers.

Inspection Focus: Thoroughly examine connection integrity using binoculars. Photograph with a telephoto lens for magnification review. Bolts may require tower climbing and torque wrench verification.

Typical Symptoms: After years of operation, metal fatigue occurs, or the zinc coating applied for corrosion protection peels off extensively, losing its protective function.

Inspection Focus: Observe whether fittings have lost their metallic luster and whether the zinc coating is peeling off in patches, exposing the base metal.

Typical Symptoms: Installation deviates from procedures. Examples include: compression bolts on bolt-type clamps not installed on the load-bearing side; contact surfaces of bushing clamps (jumper clamps) not ground or coated with electrical grease.

Inspection Focus: Requires specialized knowledge. Verify bolt orientation, contact surface flatness, and presence of required conductive grease. Such defects readily cause overheating.

Typical Symptoms: Conductive pathways may form on hardware (e.g., steel caps, steel feet) of insulator strings due to contamination and moisture, causing localized arcing and leaving irregular grayish-white burn marks.

Inspection Focus: Carefully examine the surfaces of hardware at both ends of insulators for arcing burn paths.

Typical Symptoms: In areas prone to micro-vibration (e.g., windy areas, canyons), fittings (especially conductors at clamp exits) may suffer metal fatigue fractures due to prolonged high-frequency, low-amplitude vibration. Fracture surfaces are typically clean and smooth.

Inspection Focus: Prioritize inspections in these specific sections. Check for broken strands at conductor exits from clamps and verify the effectiveness of anti-vibration devices.

Typical Symptoms: Obvious deformation, missing parts, or damage to hardware caused by construction machinery collisions, theft, gunfire, kite entanglement, etc.

Inspection Focus: Patrol the line corridor environment. Immediately conduct a thorough inspection of overhead hardware upon noticing any abnormal signs.

How to Quickly Assess Potential Risks in Hardware? (Practical Mnemonic)

To aid field personnel in assessment, remember this mnemonic: “Check color, feel tightness, measure temperature difference, inspect stress points, compare adjacent points.”

Performing these five actions covers most initial hardware inspections.

Professionals, mastering hardware defect knowledge and inspection methods is fundamental. Daily work requires multi-faceted approaches to ensure grid safety and stability.

– Never neglect routine maintenance

– Pursue continuous technical improvement

– Prioritize team collaboration

Though small, electrical fittings bear immense responsibility for the entire power system’s safety. We urge every power worker to take this seriously, enabling these unsung heroes to maximize their role within the grid and deliver stable, reliable electricity for our daily lives and industrial operations.

Every trace of rust, every crack, is a silent warning from the grid. Inspecting electrical fittings for hidden dangers is tedious, repetitive work—yet it forms the most solid defense protecting millions of homes. These “invisible guardians” beneath the silver wires, alongside their true protectors—the inspection workers—weave a safety net woven from responsibility and expertise.

Next time you gaze upon the transmission lines stretching across the sky, perhaps you’ll gain a deeper appreciation and respect for these silent “steel joints.” The stability of our power begins with these most fundamental foundations.