When terminating electrical cables, the terminal lug you select is a critical decision that impacts safety, reliability, and long-term performance. The choice often narrows down to two primary types: insulated and bare copper terminal lugs. While both serve the same fundamental purpose of creating a secure connection between a cable and a terminal, their applications and benefits differ significantly. Selecting the wrong type can lead to short circuits, corrosion, or failed inspections. This guide will clearly explain the construction, advantages, and ideal use cases for both insulated and bare copper lugs, empowering you to make the correct, safe choice for your specific electrical project. At Enviele, we manufacture both types to the highest standards, ensuring you have the right component for every connection.

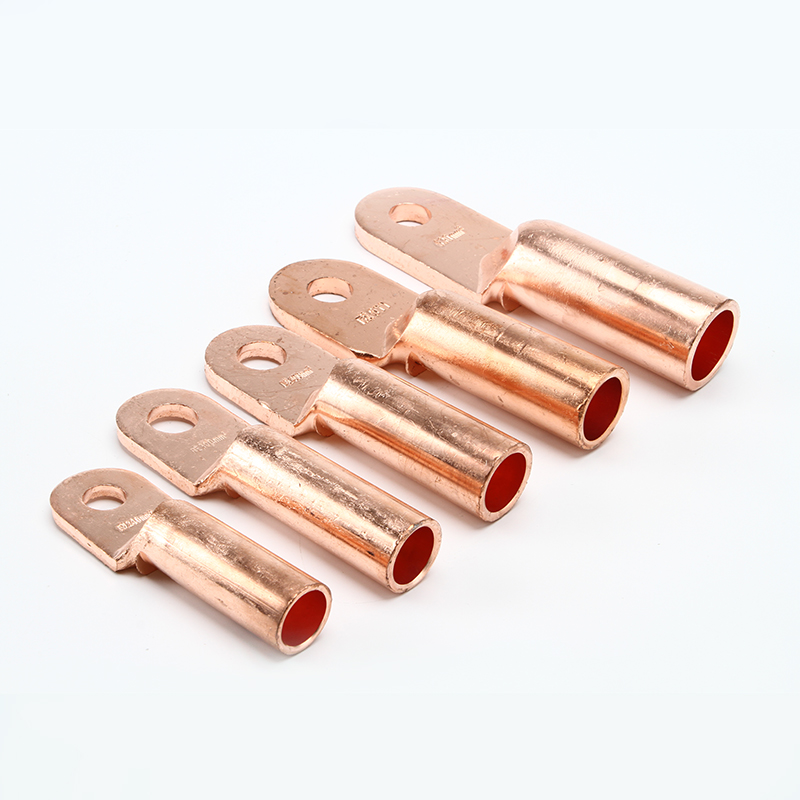

Bare copper terminal lugs are exactly as their name implies: they are made from high-conductivity copper (often tin-plated) and have no external insulating sleeve. The entire lug—the barrel for crimping and the tongue for connecting—is exposed. This design offers a direct, unobstructed path for visual inspection of the crimp quality and the condition of the copper. They are typically less expensive than their insulated counterparts and are the go-to choice in controlled, dry environments where accidental contact with other conductive surfaces is not a risk. Common applications include inside sealed electrical panels, on grounding busbars, within industrial control cabinets where spacing is precisely managed, or in high-temperature locations where insulation might degrade. Their simplicity and cost-effectiveness make them ideal for OEM manufacturing and installations where an electrician can ensure proper isolation.

Insulated terminal lugs feature a durable, color-coded nylon or vinyl sleeve that encapsulates the crimp barrel and extends partially up the wire. This sleeve provides several critical layers of protection. First and foremost, it acts as a physical barrier against accidental short circuits by preventing the metal lug from contacting adjacent terminals, wires, or grounded surfaces. Second, the insulation offers strain relief, reducing stress on the copper crimp joint from vibration or cable movement. Third, the insulation provides a degree of environmental protection against moisture, dust, oils, and incidental abrasion. The color coding (e.g., red for 16-14 AWG, blue for 12-10 AWG, yellow for 8-6 AWG) also aids in quick wire size identification. These lugs are the standard for most field wiring, automotive applications, marine use, and any location where wires are bundled or routed in close quarters.

The table below provides a clear, side-by-side comparison of insulated and bare copper lugs across the most important decision-making criteria.

| Feature | Bare Copper Terminal Lugs | Insulated Terminal Lugs |

|---|---|---|

| Primary Protection | None (metal is exposed). | Nylon/Vinyl sleeve guards against shorts, abrasion, and contaminants. |

| Safety Level | Lower. Requires careful installation and spacing to prevent faults. | Higher. Provides a critical safety barrier in crowded or exposed applications. |

| Environmental Resistance | Low. Exposed copper is susceptible to oxidation and corrosion in damp or harsh conditions. | Moderate to High. The sleeve protects the barrel from moisture, dust, oils, and chemicals. |

| Visual Inspection | Excellent. The entire crimp and wire can be seen for quality assurance. | Limited. Only the wire entry and tongue are visible; the critical crimp is hidden. |

| Cost | Generally lower cost per unit. | Higher cost due to additional material and manufacturing. |

| Installation Requirements | Must be installed in a fully insulated environment (e.g., inside a panel). | Can be installed in exposed or semi-exposed conditions. |

| Temperature Rating | Limited only by the copper/tin plating. Can withstand very high heat. | Limited by the insulation material (typically up to 105°C/221°F for nylon). |

| Best For Applications | Grounding connections, interior of sealed enclosures, high-temp zones, busbars. | General field wiring, automotive, marine, control panels with wire bundles, outdoor equipment. |

Making the right choice is straightforward when you evaluate your project’s specific conditions. Follow this decision guide:

Assess the Physical Environment: Is the connection located in a sealed, dry, and clean enclosure with guaranteed spacing? A bare lug may be suitable. Is it in a damp, dusty, oily, or exposed area where wires are bundled? An insulated lug is mandatory for safety.

Prioritize Safety and Code Compliance: For most commercial, residential, and automotive wiring, electrical codes and best practices heavily favor or require insulated terminals to prevent short circuits. When in doubt, choose insulated.

Consider Inspection and Maintenance: If the connection requires frequent visual inspection for corrosion or crimp integrity (e.g., in some industrial settings), a bare lug has an advantage. For permanent, “set-and-forget” installations, the hidden crimp of an insulated lug is acceptable.

Evaluate Thermal and Space Constraints: For connections near heat sources like transformers or engines, verify the insulation material’s temperature rating. In extremely tight spaces, the added bulk of insulation must be accounted for, though its protective benefit is often most valuable there.

As a rule of thumb, insulated lugs should be your default choice for general-purpose wiring.Reserve bare copper lugs for specific, controlled applications like grounding or within professionally assembled panels where the entire environment is insulated.

Regardless of type, proper installation is non-negotiable. Always use a calibrated crimping toolmatched exactly to the lug’s wire size range. An improper crimp is the leading cause of failure. For insulated lugs, ensure the wire strip length is correct so that no conductor is exposed at the front, and the insulation butt of the wire rests inside the rear of the sleeve. For bare lugs, after crimping, consider applying a non-corrosive antioxidant compound if the environment is not perfectly dry, and always ensure adequate physical clearance (creepage and clearance distance) from other components.

For most projects, insulated terminal lugs are the safest and most versatile choice, providing essential protection against shorts and environmental factors. Bare copper lugs are a specialized, cost-effective solution for controlled, high-temperature, or grounding applications within insulated enclosures. Your project’s environment, safety requirements, and codes should guide your final selection. For a complete range of reliable, compliant insulated and bare copper lugs, explore Enviele’s catalog. Contact our technical support team today for personalized advice to ensure your connections are secure, safe, and built to last.

Q: Can I put heat-shrink tubing over a bare copper lug to insulate it?

A: Yes, this is a common and effective practice. It allows for visual inspection of the crimp before applying the tubing and creates a custom, environmentally sealed insulation.

Q: Are insulated lugs more difficult to crimp properly?

A: No, the crimping process is identical. High-quality insulated lugs have inspection holes in the sleeve to allow you to verify the wire is fully inserted before crimping.

Q: Is the tin plating on bare lugs necessary?

A: Highly recommended. Tin plating prevents oxidation of the copper, maintaining a low-resistance connection over time, especially in humid environments.

Q: Can I use an insulated lug in a high-temperature environment (e.g., near an engine)?

A: Only if the lug’s insulation material is rated for the expected temperature. Standard nylon may melt. For high-temp apps, use bare lugs with high-temperature heat-shrink or lugs with specialty insulation.

Q: Why choose Enviele for terminal lugs?

A: Enviele provides precision-engineered lugs with consistent quality, ensuring secure crimps and reliable conductivity. Our products meet industry standards, and our expertise helps you select the right type for optimal safety and performance in your application.