In industrial facilities, power generation plants, and large-scale renewable energy installations, electrical systems are pushed to their limits. Standard electrical connections simply cannot withstand the immense currents, intense vibration, and thermal stresses present in these environments. This is where heavy-duty industrial copper lugs become non-negotiable. Engineered with specialized designs and superior materials, these components are the critical link that ensures safety, reliability, and efficiency in high-current applications. Using an underspecified lug can lead to catastrophic failures, including overheating, meltdowns, and arc flashes. This guide explores the unique designs of heavy-duty lugs and explains how to select the right one for your most demanding power distribution challenges. At Enviele, we specialize in manufacturing robust, high-performance copper lugs built to handle the extreme demands of industrial applications.

High-current applications present unique challenges that standard lugs are not built to withstand. The primary issue is excessive heat generation due to I²R power loss. Even a small amount of increased resistance at the connection point can generate dangerous temperatures at currents of 400A, 800A, or higher. Standard lugs may have insufficient cross-sectional area or wall thickness, leading to hot spots. Furthermore, industrial settings often involve severe vibration from machinery, which can loosen mechanical connections, and thermal cycling that causes expansion and contraction, degrading the connection over time. Heavy-duty lugs are specifically engineered to combat these forces with enhanced material purity, greater mass, and innovative design features that maintain a low-resistance, gas-tight connection under relentless operational stress.

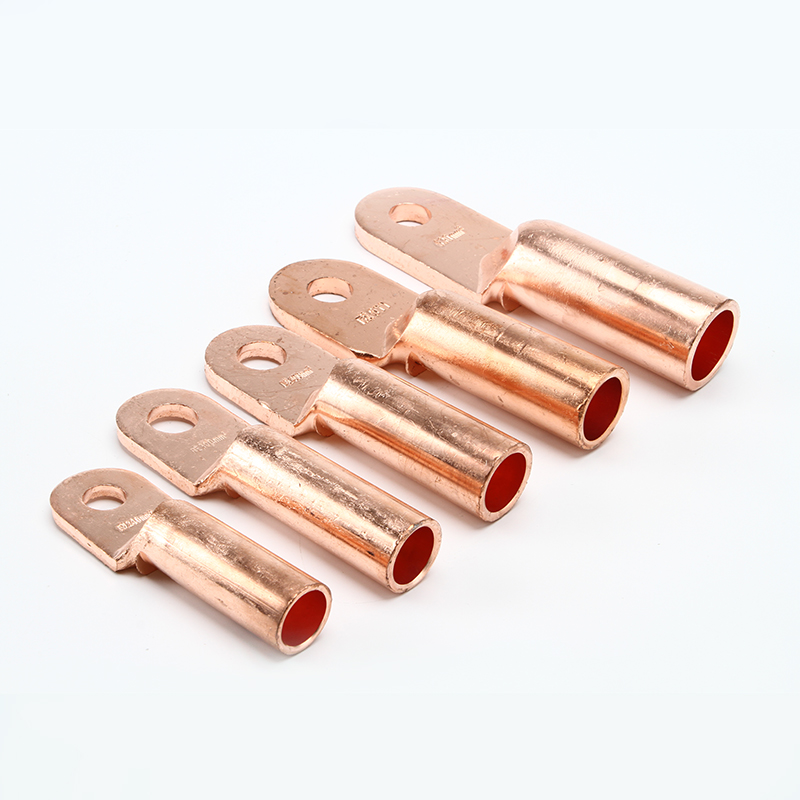

Heavy-duty lugs distinguish themselves through several critical design enhancements that go beyond basic form and function.

Enhanced Material and Construction: They are typically manufactured from high-purity, high-conductivity copper (C11000) with a uniform, thick tin plating to prevent oxidation. The barrel wall is substantially thicker than that of a standard lug, providing greater mechanical strength, a deeper crimp area, and a larger thermal mass to dissipate heat.

Specialized Tongue Designs: The connection tongue is reinforced and optimized for high pressure. Common heavy-duty designs include parallel groove tongues (for even pressure distribution on busbars), two-hole or four-hole mounting patterns (to prevent rotation and ensure even clamping force on large conductors), and offset or angled tongues to facilitate easier installation in crowded panels.

Sealing and Inspection Features: Many heavy-duty lugs include inspection holes to verify the wire is fully inserted before crimping. Some are designed to be used with heat-shrink tubing seals that provide environmental protection against moisture and corrosion, which is crucial in mining, marine, or outdoor renewable applications.

Different high-current scenarios call for specialized lug designs. The table below outlines the most common types and their primary industrial uses.

| Lug Type & Design | Key Features | Ideal Industrial Application |

|---|---|---|

| Heavy-Wall Two-Hole Ring Lug | Extra-thick barrel; two bolt holes for superior mechanical locking and contact surface. | Permanent, high-vibration connections to busbars in switchgear, power panels, and generator sets. |

| Parallel Groove (PG) Clamp Lug | Tongue has a smooth, flat groove for maximum surface contact with busbars. | Main power feeder connections, utility metering equipment, and any bolted busbar interface. |

| Palm/Feed-Through Lug | A long, flat tongue with multiple bolt holes, often with an insulated barrier. | Connecting large cables to circuit breaker inputs/outputs or creating through-panel connections in distribution boards. |

| Bimetallic Lug (Aluminum to Copper) | One side is copper for cable termination; the other is aluminum for connecting to aluminum busbars. | Critical in facilities with aluminum busbar systems (common in older plants) to prevent galvanic corrosion. |

| Heavy-Duty Pin Lug | Reinforced pin with a large diameter for high-current pin-and-socket systems. | High-amperage plug-in connections for removable breaker racks or large equipment disconnects. |

Choosing the correct lug is a systematic process. Relying on guesswork is not an option. Follow this essential checklist:

Current Rating (Ampacity): This is the foremost criteria. The lug must have a verified ampacity rating that meets or exceeds the system’s maximum continuous current, with a safety margin. Consult manufacturer charts, which are based on UL/CSA/IEC standards.

Cable Size Compatibility: Precisely match the lug’s cable range (in mm² or AWG) to your conductor size. A mismatch will result in an unsafe crimp.

Hole Size and Pattern: Verify the bolt hole diameter and spacing matches your terminal stud or busbar hardware. A two-hole lug is always preferred over a single-hole for high-current connections to prevent pivoting.

Material and Plating Specification: Ensure the lug is made from high-conductivity copper (C11000) and features a thick, uniform tin plating for corrosion resistance. For aluminum connections, you must specify a bimetallic lug.

Environmental and Regulatory Needs: For harsh environments, select lugs compatible with sealing adhesive-lined heat-shrink. Ensure the product is UL listed, CSA certified, or IEC compliant for your project’s location and industry.

Even the best lug will fail if installed incorrectly. For heavy-duty applications, precision is paramount.

Use the Correct Tool: Always use a calibrated, high-pressure hydraulic crimping tool with the exact die set specified by the lug manufacturer. Hand tools are insufficient for these large conductors.

Prepare Surfaces: Clean the stripped cable conductor and the inside of the lug barrel with a specialized electrical cleaning solution to remove oxides and contaminants.

Apply Compound: Use a conductive antioxidant compound on the conductor and inside the barrel before crimping. This fills microscopic air gaps, prevents future oxidation, and improves conductivity.

Crimp and Verify: Execute the crimp in the correct sequence as per the tool/lug instructions. After crimping, perform a visual inspection and a pull test to ensure mechanical integrity. For bolted connections, use a torque wrench to achieve the exact manufacturer-specified tightness.

Seal the Connection: For outdoor or corrosive environments, apply adhesive-lined dual-wall heat-shrink tubing over the crimp barrel to create a waterproof, sealed termination.

For high-current industrial applications, heavy-duty copper lugs are a critical investment in system safety and uptime. Their specialized designs—from reinforced two-hole rings to bimetallic transitions—solve the unique challenges of ampacity, vibration, and corrosion. Selection must be based on precise electrical and mechanical specifications, followed by expert installation. Do not compromise on the component that carries your highest power loads. For certified, high-performance heavy-duty industrial lugs, explore the Enviele range. Contact our engineering support team today for personalized technical data and selection guidance.

Q: What is the main visual difference between a standard and a heavy-duty lug?

A: Heavy-duty lugs have a noticeably thicker barrel wall, larger physical dimensions for the same wire size, and often feature two-bolt holes instead of one for increased clamping force.

Q: Can I use a heavy-duty lug on a smaller cable for “extra safety”?

A: No. Using a lug rated for a much larger cable will result in an improper crimp, even with the correct die. Always match the lug’s listed cable range exactly to your conductor size.

Q: Why is tin plating so important?

A: Bare copper oxidizes quickly, forming a high-resistance layer. Tin plating prevents this oxidation, maintains a low-resistance surface, and provides better compatibility with aluminum when used with bimetallic lugs.

Q: How do I know the current rating (ampacity) of a lug?

A: Reputable manufacturers like Enviele provide certified ampacity charts based on testing standards (e.g., UL 486A-B). This rating depends on the lug design, material, and the connected cable size.

Q: Why choose Enviele for heavy-duty industrial lugs?

A: Enviele designs and manufactures lugs to the highest material and construction standards. We provide complete technical specifications, compliance certifications, and application support to ensure you select a lug that guarantees reliability, safety, and performance in your most critical high-current connections.